Definition of basic parameters of the rotating group and pump operating conditions:

| Parameter | Symbol | Units | Notes |

|---|---|---|---|

| Number of pistons | z | - | Takes integer values between 1 and 99 and needs to satisfy zmax equation. |

| Piston diameter | dp | mm | Must be positive value |

| Piston pitch diameter | Dp | mm | Has to be greater than piston diameter dp |

| Swashplate angle | β | degree | Typical value below 23 degrees for axial piston machines. |

| Parameter | Symbol | Units | Notes |

|---|---|---|---|

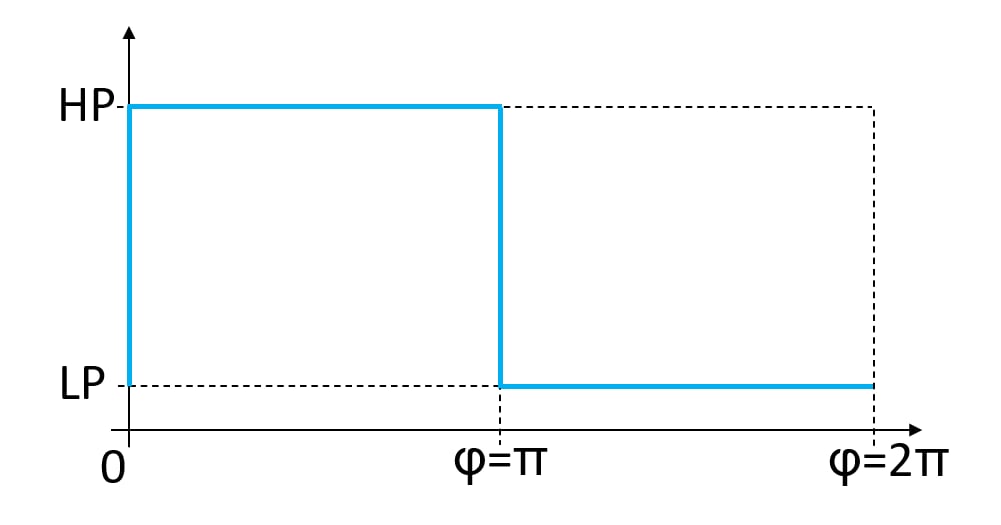

| Outlet pressure | HP | bar | Must be positive |

| Inlet pressure | LP | bar | Must be positive |

| Speed | n | rpm | - | Must be positive

Angle between each piston is (2π/z)

The simulation is only run for numerically possible designs when the wall thickness wt between bores is greater than 0. For a given piston diameter dp and piston pitch diameter Dp, the maximum number of pistons z is defined by assuming a wall thickness of zero and round down to closeset integer:

Actual wall thickness according to input data is caluclated based on the following:

Simulation of the main pump characteristics:

The geometric displacement volume Vg of an axial piston pump is a function of basic dimensions:

The theoretical pump flow is the product of displacement volume and speed:

The theoretical input torque is a product of geometric displacement volume Vg and differential pressure between inlet and outlet lines (Δp = HP − LP):

Simulation of the continuous flow:

The graph in "Kinematic Flow" tab shows the flow rate of each piston and the total output flow Q of the pump during one shaft revolution. The pump flow rate is not constant but pulsating and is a function of each piston area and speed vpi. The mean value corresponds to the theoretical flow rate of the pump Qtheo.

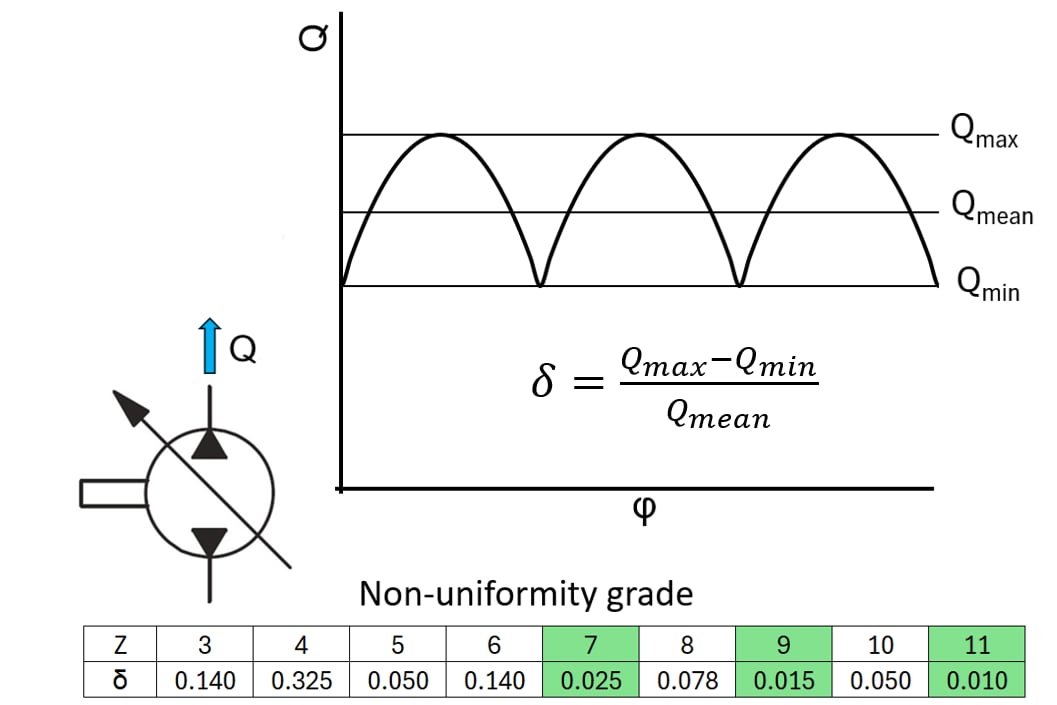

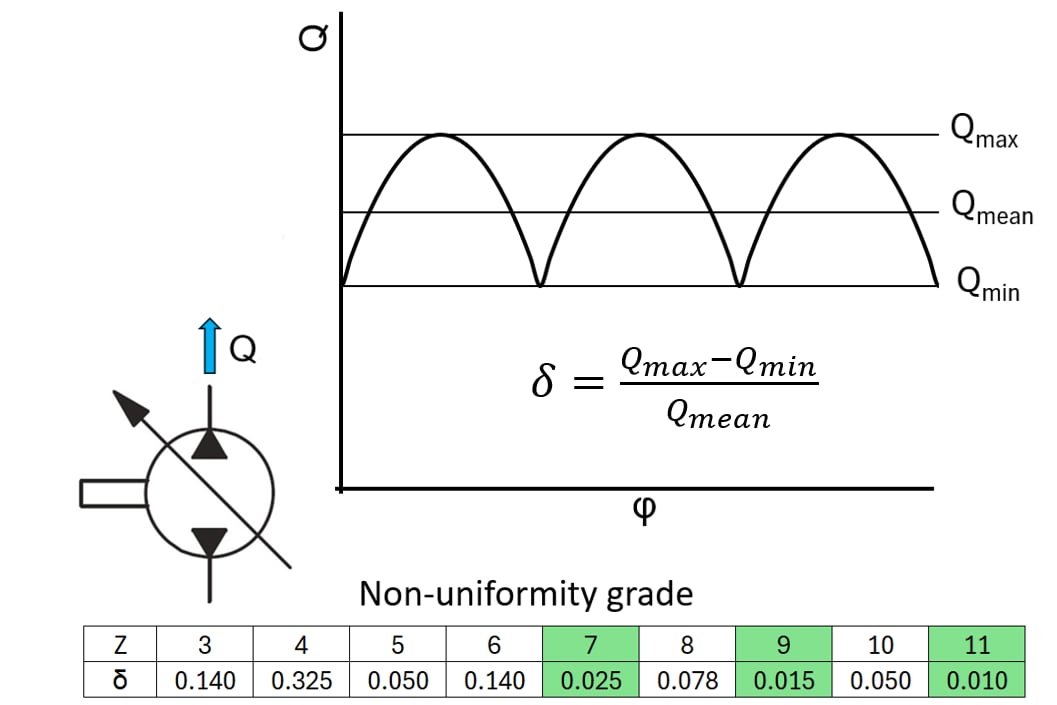

Non-uniformity grade δ characterizes the flow pulsation.

The graph in "Torque" tab shows the torque from each piston and the total input torque of the pump during one shaft revolution. The pump flow rate is not constant but pulsating. The mean value corresponds to theoretical input shaft torque Ttheo.

Simulation considers ideal displacement chamber pressure behavior:

Simulation of piston kinematic parameters during one shaft revolution

The piston displacement sp is proportional to the pitch diameters of pistons Db, the swash plate angle β and on actual angular position φ:

Axial velocity of individual piston-slipper subassembly vp is derived from the piston stroke and its angular position φ:

Where ω is shaft angular velocity.

Further derivation yields an acceleration of the piston-slipper subassembly ap:

The simulation results summary in tabular format. You can copy the data by clicking the icon